- 미등록페이지

- Best Partner & First Company

2018.01.25

관리자

Designing and Manufacturing

Chocolate & Jelly Plant

-

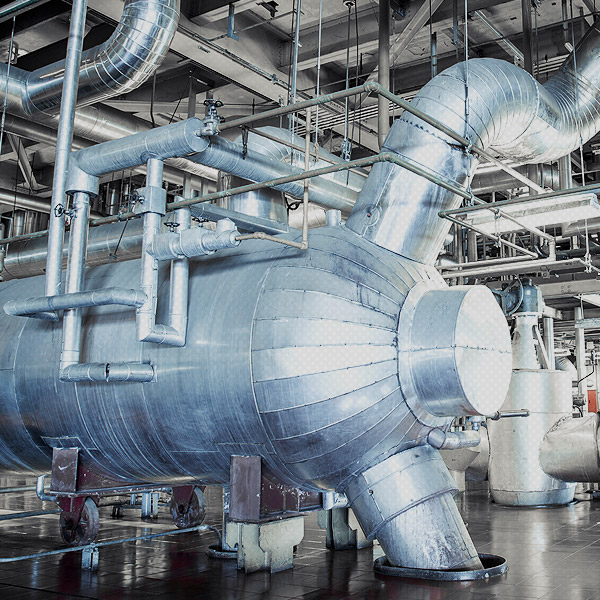

Asan ENG Co., Ltd. has various know-how through the turnkey base project related to chocolate plant.

Through collaboration with the best chocolate companies in the world, we have improved our understanding

of chocolate production and facilities, and we have acquired the know-how and technology related to this.

In addition, we are designing and manufacturing jelly product production facilities

in 2017 and have been recognized for its technological prowess both inside and outside.

In particular, the technology of dispensing chocolate and jelly products has a high level of knowledge and know-how compared to other competitors.

Chocolate Plant

- We have various know-hows through DROP ROLL, CHUNK CUTTER, and many other chocolate related projects.

-

Drop Roll M/C Capacity 400~1,000㎏ / Hr. Molding Volme : 0.9 ~ 3.5㏄ / 1ea Type Ice Drop Roll Molding. Temperature : -25℃ Roll R.P.M 0.9 ~ Max` 1.5. Inverter Dimension W2. 200 x L 1,500 x H 1,900 Material Frame & Cover : S45C & SUS304. Depositer & Nozzle : A7071 & SUS304. Accessaries : A7071 & SUS304 E. Power & Control 2.25㎾ (220 / 380v*3p). Drive Moter Cold / Hot Water Cold Brine 40A / Hot Water 25A. Pipings Weight 2,200㎏ -

Chunk Cutter M/C Capacity 600~1,000㎏ / Hr Cutting Size : W 8~13. L 8~13. H 7~12 / 1ea. Type Slitting & Guillotine Cuctting Cutting Stroke Max` 120/min. Inverter Dimension W 2,200 x L 1,500 x H 1,900 Material Frame & Cover : S45C & SUS304. Accessaris : A7071 & SUS304 E. Power & Control 13㎾ (220/380v*3p). Drive Moter : Slitting & Guillotine Cuctting Weight 2,400㎏

Turn Key Base Project in China

Jelly plant

-

Asan ENG Co., Ltd. has developed jelly depositing technology based on numerous failures

and experiences and also designed and manufactured production automation plants.

| Capacity | 600㎏/hr ~1000㎏/hr |

|---|---|

| Jelly Mass | 5g ~ 30g (Customizable) |

| Composition | 1.Stacker 2.Starch transfer system 3.Depositor 4.Syrup Coating System 5.Mold Production |

| Control | Touch Panel |

2017.12.14

관리자

Plant Consulting

Total Engineering

-

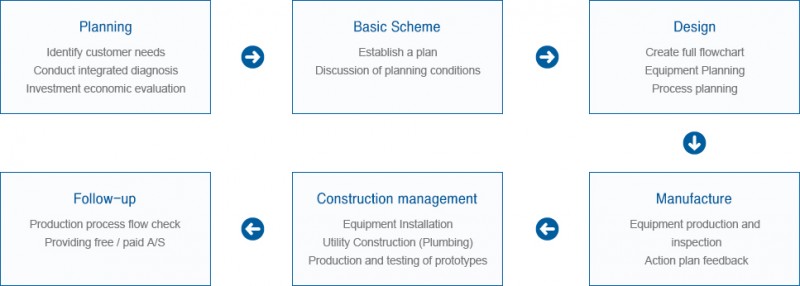

Asan ENG Co., Ltd. provides a more optimized production environment by raising

the possibility of company growth with new thinking and quick movement.

As a professional company that provides total engineering solutions from infrastructure of production environment

to production facilities, we have a passion for creating the best solution and a dream for creating the best value in the world.

Asan ENG Co., Ltd. is also challenging today.

Plant Consulting

-

Asan ENG Co., Ltd. is providing the best solutions to build the products and environment that customers want

from the design of food and confectionery production facilities to the whole area of design and production automation.

Total Engineering

-

Based on the rich experience accumulated since the foundation of the company and more than 20 years of talent

in the field of food, we realize total engineering of food and confectionery production equipments with the highest productivity and efficiency.

Food manufacturing

facilityProduction

Flow DesignCustomized Equipment

ProductionProcess

automation

2017.12.14

관리자

One-stop System

Mold Process

-

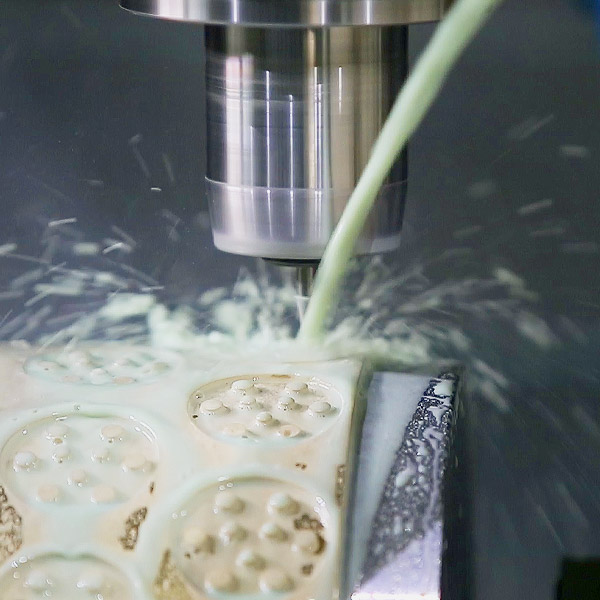

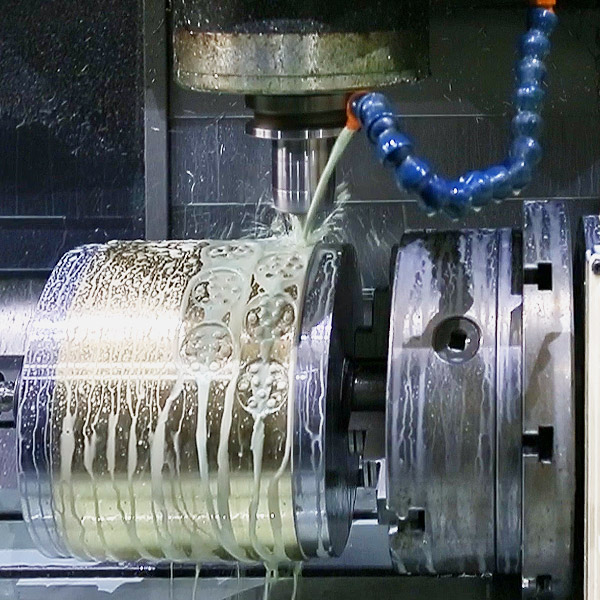

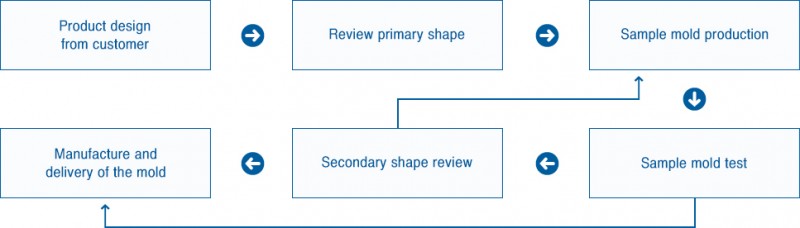

Mold production refers to a mold made of metal for mass production of products with a certain shape.

Durability is important for mass production, so it is made of alloy to increase durability.

Asan ENG Co., Ltd. produces biscuits and ice cream molds professionally. Other molds can also be produced and consulted.

Process

One-stop System

- Asan ENG Co., Ltd.

-

produces high quality molds from the beginning to the final production through the ONE STOP SYSTEM equipped with state-of-the-art facilities for all production processes from design to manufacture and delivery.

In particular, unlike other competitors, MCT processing equipment is directly processed at the factory, so it can be delivered at the most competitive price.

Asan Strength

- Technology

- Over 20 years in the field of food and confectionery products, we have various know-how through the production of molds to suit the characteristics of our customers' products.

- Reasonable price

- It is possible to reduce the cost through MCT processing equipment. We have know-how to save cost through various product.